When it comes to understanding the inner workings of electric motors, identifying the starting and running windings is crucial. These windings play a fundamental role in the operation of the motor, and being able to distinguish between them is essential for maintenance and troubleshooting. Join me as I delve deep into the intricacies of starting and running windings, shedding light on how to identify and differentiate between them.

Understanding Starting Windings

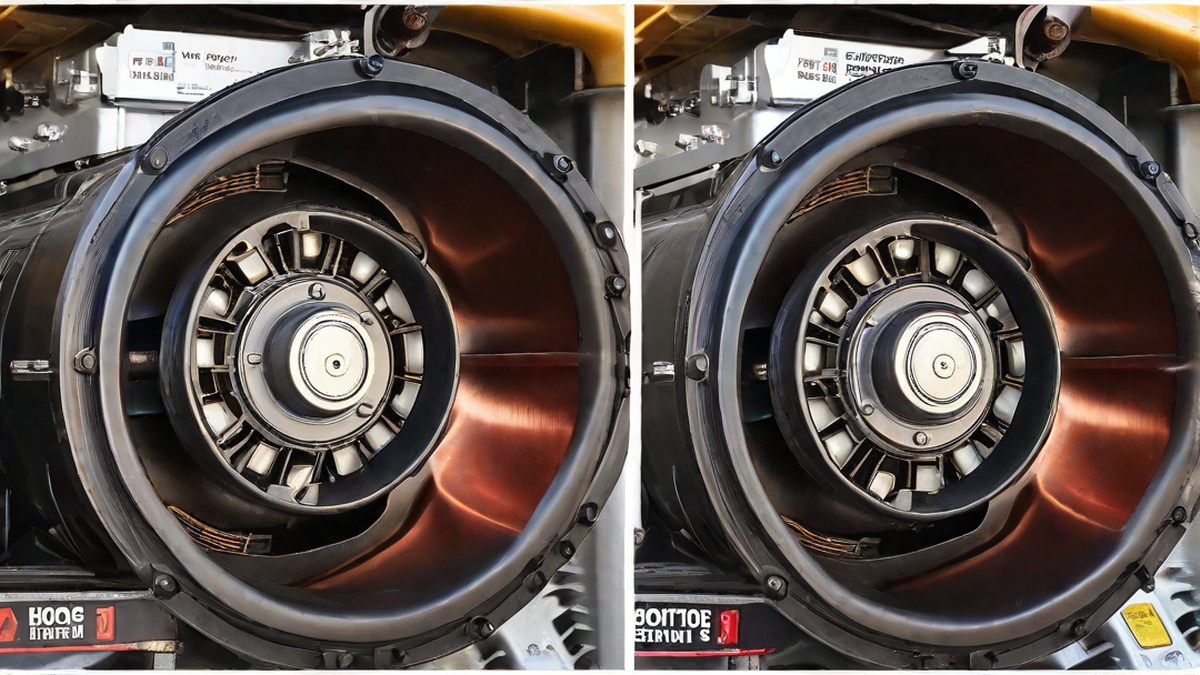

The starting windings in an electric motor are designed to provide the initial torque needed to start the motor. They are typically made of a heavier gauge wire and are only active during the starting phase. Once the motor is up to speed, a switch mechanism, such as a centrifugal switch or a potential relay, disconnects the starting winding from the power source. This prevents the starting winding from overheating during continuous operation.

Identifying Starting Windings

To identify the starting winding in a motor, you can begin by locating the wiring diagram for the specific motor model. The starting winding is often labeled as “S” or “STA” on the diagram. If the diagram is not available, visually inspecting the motor windings can also provide clues. Starting windings typically have a greater number of turns and use thicker wire compared to the running winding.

Understanding Running Windings

On the other hand, the running windings are responsible for maintaining the motor’s continuous rotation once it has started. These windings are made of thinner wire and are designed to handle the motor’s running load efficiently. Unlike the starting windings, the running windings remain connected to the power source throughout the motor’s operation.

Identifying Running Windings

Similarly, the running windings can be identified through the wiring diagram or visual inspection. On the diagram, the running winding is typically labeled as “R” or “RUN.” Visually, the running windings will have fewer turns of thinner wire compared to the starting windings.

Personal Tips for Identification

From my experience, using a multimeter can be incredibly helpful in differentiating between the starting and running windings. By measuring the resistance of the windings, you can typically identify the starting winding as having a higher resistance due to its thicker wire and more turns, while the running winding will have lower resistance due to its thinner wire and fewer turns.

Conclusion

Identifying the starting and running windings is an essential skill for anyone involved in the maintenance or repair of electric motors. Whether you rely on wiring diagrams or visual inspection, understanding the differences between these windings is crucial for ensuring the efficient and safe operation of electric motors.